|

|

|||

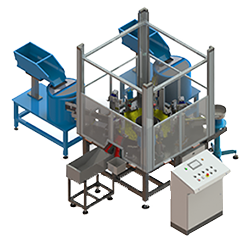

Fully automatic assembly/machining isle with rotating table; the operator's support is limited to a control process or, at maximum, to the feeding of the raw product.

The machining is organized on a number of stations furnished by customer's specifications, depending on the necessaries phases to get the final product.

The whole machine is furnished to work in a total safety way, preventing the access at the machining area to the operator.

Every isle is provided with a product control, managing at the end of the cycle to perform a division between "good pieces" and wastes.

Every isle can work in total independence or be part of a more complex system, both composed by other satellite isles or by external machines.

Examples of possible applications are: assembly of small and difficult-in-handling particulars, laser marking of components and quality control with vision systems of products.

The isle id furnished complete by CE safety certification and by owner and maintenance handbook.

|

|||

|

|

| ||

FROM RAW TO FINISHED PRODUCT WITH TOTAL CONTROL

FROM RAW TO FINISHED PRODUCT WITH TOTAL CONTROL