THE QUALITY YOU ALWAYS LOOKED FOR AT THE PRICE OF YOUR DREAMS

THE QUALITY YOU ALWAYS LOOKED FOR AT THE PRICE OF YOUR DREAMS

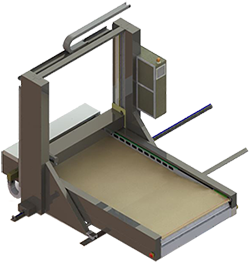

Automatic oven loading and unloading system, with high quality/price ratio.

The automatic put-into-the-oven loader model "SMART BASIC" is able to manage two ovens with two shelves at maximum, anyway it depends on the cooking time of the product to cook.

Other characteristics:

- Loading bed supporting structure made of extrude high resistance aluminium bars

- Components made of AISI 304 stainless steel

- Omron basic electronics

- 10" Touch Screen panel

- Brushless motors joined with Italian production high precision speed reducers

- Movements quenched gears with rectified profile

- Electric switchboard and carters made of oven painted metal sheets

Optional:

- Carters made of AISI 304 stainless steel

- Air-conditioner for electric switchboard

- Module for via internet remote assistance

- Equipment for the electronic and analogic managing of the ovens

This loader can be coupled with these preload configurations:

- Preload motorized belt

- Preload system with product withdrawal from tablets

- Product gathering system from the baking loader

In the first the operator deposits the bread in ordered rows (aligned with lateral references) and pushes a button to make the belt to do a step movement.

At the end of the (programmed) steps the preload arrange itself with the bread on its extremity waiting for the loader makes it to pass from a belt from the other, to finally put the bread into the oven inside the selected chamber already set before to the desired cycle.

It is possible to provide the plant with an unload buffer (optional), its function it is to unload rapidly the cooked from the loader, then the operator can unload with a manual command directly from the from the baskets posed at the ground below the belt level.

In the second case, the put-into-the-oven loader model "SMART BASIC" it is coupled with a preload system with product withdrawal from tablets.

The operator gets from a trolley the tablets with the product to be cooked and deposits at the designed location.

When the related button has been pressed a translation system moves the tables towards the blue preload belt passing the product from the tablets to the belt.

The tablets movements inverts its direction coming towards the operator. He then withdrawals the empty tablets and rearranges the full ones.

The process proceeds in this way up to the blue belt is not completely fed and the machine arranges itself with the bread at the extremity for the transferring on the loader and the successive put-into-the-oven phase.

Even in this configuration it is possible to couple an unload buffer (optional).

In the last case, the operator positions the trolley filled with the baking loaders with the dought product to be cooked deposited above, inside an apposite station and finally furnish the consent to proceed.

So, thanks to a hydraulic system, the trolley is lifted at the loader gathering height.

When it is in position, the loader receives the consent to the gathering and it will autonomously provide to gather the dough product from a baking loader to the other and to put the it into the oven.

When even the last baking loader will be accomplished, the operator will receive an acoustic warning and he will provide for the trolley substitution.

In all cases, the plant is furnished with protections for the working area (perimetral enclosure, safety light curtains or laser scanner), maintenance and owner handbook and CE certification.

THE QUALITY YOU ALWAYS LOOKED FOR AT THE PRICE OF YOUR DREAMS

THE QUALITY YOU ALWAYS LOOKED FOR AT THE PRICE OF YOUR DREAMS