THE CUTTING EDGE OF THE OVEN LOADING TECHNOLOGY

THE CUTTING EDGE OF THE OVEN LOADING TECHNOLOGY

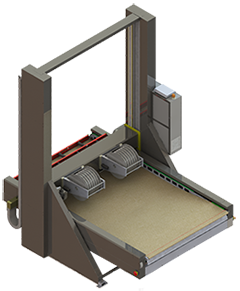

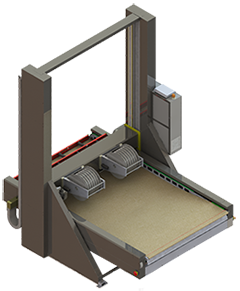

High quality automatic put-into-the-oven loader and unloader with excellent robustness and reliability during the time.

The automatic put-into-the-oven loader model "SMART TOP" is able to manage up to four ovens with four shelves, anyway it depends on the cooking time of the product to cook.

Other characteristics:

- Loading bed supporting structure made of extrude high resistance aluminium bars

- Components made of AISI 304 stainless steel

- Omron electronics

- 12" touch screen panel

- Omron brushless motors with field bus (mekatrolink) coupled with Italian production precision speed reducer with low mechanical play

- Quenched gears with rectified profile

- Carters and switchboards made of AISI 304 stainless steel

- Predisposition for via internet remote assistance

Optional:

- Air-conditioner for electric swithboard

- Equipment for the electro-mechanical and analogic managing of the ovens

- Vacuum system for cleaning cycle

- Normally it is furnished with the tablets preload system.

The operator withdrawals the tablets with the product to cook from a trolley and deposits them at the designed location.

Whn the command button has been pressed, a translation system moves the tablets towards the preload blue belt passing the product from tablets to the belt.

The tablets movements goes on under the preload belt and successively they are translated and piled inside a trolley next to the machine.

The trolley gets full progressively as the operator loads the belt up to the fully trolley advice and automatically prepare for the change with the empty trolley.

The process proceeds in this way up to the blue belt is not completely fed and the machine arranges itself with the bread at the extremity for the transferring on the loader and the successive put-into-the-oven phase.

The machine is able to manage different kind of cyles: Manual, Semi-automatic and Automatic.

In the same way it is possible to memorize recipes that keep into account the ccoking time, vapour valve opening time, chimney valve opening and oven temperature for the different products.

It is possible to couple the product to cook with the oven shelve and to the desired oven itself (e.g. when one desires to cook a different product for every oven).

The plant is furnished with protections for the working area (perimetral enclosure, safety light curtains or laser scanner), maintenance and owner handbook and CE certification.

THE CUTTING EDGE OF THE OVEN LOADING TECHNOLOGY

THE CUTTING EDGE OF THE OVEN LOADING TECHNOLOGY