|

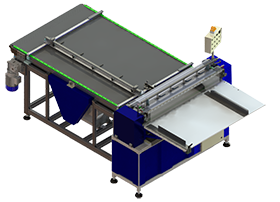

Gluing machine RAFFAELLO |

THE COMPLETE OFFER FOR ANY NEEDS THE COMPLETE OFFER FOR ANY NEEDS

The machine allows to glue and to bind multiple typologies of cardboards and bookbinding materials, having a wide range of products such as binders, covers, photographic albums, etc. Using cold or hot glue with glue heater tank and recirculating pump, mixer and viscometer (OPTIONAL), sheet weight from 80 to 250 g/sm.

It is available with an induction space of 75, 105 and 120 cm and in the semiautomatic or automatic (only coupled with the complete line) version.

The machine is equipped with a stainless steel high diameter double roll system that provides the glue spread on the sheet surface uniformly while it is supported by two chromate-plated (or Teflon coated, depending on the version) parallel rolls. They are equipped with an automatic transmission chain tension adjustment. All the pinions have been oversized and quenched; the transmission chain is nickel plated. These solutions allows a lower wear and a longer duration.

The glue rolls can be reconditioned and easily extracted from the machine: in this way it is possible to extend the machine life, amortizing so the purchase even for low annual production.

The rolls rotation is made with a mixed toothed belt-gears system with an automatic recover of the belt tightening and the alternation with steel and fibreglass reinforced nylon toothed gears.

In this way we have at the same time a longer duration and the noise reduction during machine working.

The glue pump it is made in Italy, it has an aluminium frame and the sliding inside elements made of stainless steel, it is equipped with anti-stall pneumatic system, it does not need lubricated air and allows the no-load working condition with suffer. It can be reconditioned with the specific spare kit.

The feeding and the return pipes are made of PVC with internal steel spiral with an high thickness.

The glue distributor is made with a square stainless steel pipe with machined and TIG welded tap joints.

4 or 5 taps are present (depending on the machine version) for a better glue feeding adjustment.

Modular elements completing the machine:

- High-stack paper feeder BOTTICELLI:

- Combined sheet withdrawal, aspiration and transportation through holed belts for the front side, instead with a singularizator with blower;

- Feeder with automatic level control;

- Wrong double sheet withdrawal control;

- Square ruler regulator with lateral reference points and friction spheres on conveyor belt;

- Adjustable speed through inverter;

- Change of the sheet size facilitated from easy adjustments on graded scale and digital visualizers;

- Removable from the gluing group for the manual alignment of the cardboard over 250 g/sm and the maintenance.

- Aspirating belt with length of 250 cm:

- Stopping device with square ruler regulator for the positioning of the cardboard, for articulated covers and folders and for the flyleaf;

- Vacuum system through a centrifugal fan and air-box with a wide air reserve, integrated in the machine frame;

- Pneumatic controlled aspiration shutter, without fan stop inertia for manual handling of the sheet;

Optional: exiting calender roll with adjustable pressure.

Outbound calender:

- It allows the sheet to adhere and to eliminate the eventual air bubbles or folds;

- Vulcanized high thickness rolls;

- Adjustable pressure and introducing height;

- Equipped with an inverter for the speed tuning;

- Collection board at the end equipped with an easy and quick lock-unlock system.

Glue-heater tank with mixer and viscometer:

- Fully made of stainless steel;

- Electric helix mixer;

- Viscometer made in Italy for the automatic managing of the glue viscosity and touch-screen display;

- Insulated frame through a double chamber with ceramic insulator;

- Possibility to choose between the version coupled to a line or the independent version equipped with its electric switchboard and with a robust stainless steel electro-welded frame for an easy movement.

|

THE COMPLETE OFFER FOR ANY NEEDS

THE COMPLETE OFFER FOR ANY NEEDS